Brush Sander Machine for MDF

Product Description

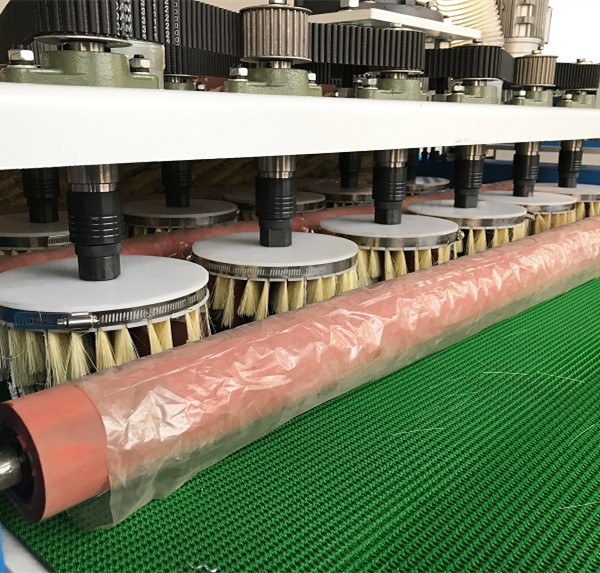

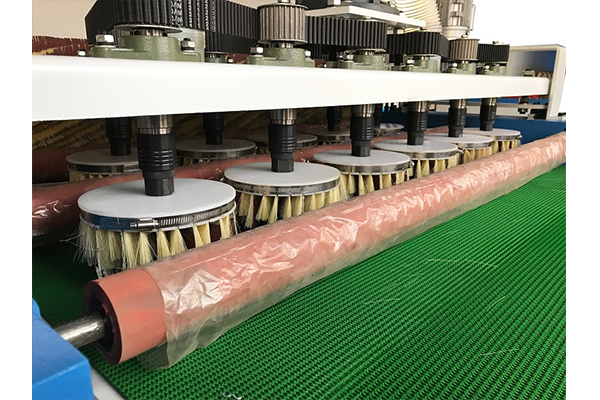

The Brush Sander Machine is composed of a sisal grinding wheel and a grinding wheel, one roller, one machine with two rollers, two-way forward and reverse grinding. It adopts multi-gradient grinding wheel tooth profile, combined with electric lifting to control the height of the roller group, for effective grinding of sheet surface milling or engraving simple grooves, etc., easy to operate, the combination of the two can grind complex and special-shaped flat plates at one time, with better results.

The Brush Sander Machine has an independent lifting structure and frequency conversion speed control, which is convenient for the pressure control and sanding speed of each sanding I sequence, and can meet the sanding requirements of different process products. The special-shaped sanding machine is one of the main production equipment of the furniture factory, and its work efficiency and work quality directly affect the production of the furniture factory.

Advantage

1. The Brush Sander Machine is suitable for all kinds of solid wood boards, composite boards, density boards, primers, white stubble, whether it is a regular surface, a special-shaped surface and a curved surface, it can be rough and finely polished, and the wood surface has a significant sanding effect.

2. The disc sand uses a large number, intricately arranged vertical grinding discs, to prevent the phenomenon of missing grooves, and is equipped with a quick-change connector, which makes it easy to replace the sand strips.

3. The longitudinal grinding roller adopts the principle of centrifugal movement, it takes a short polishing and deburring time, the efficiency is increased by more than 6 times, and it saves labor and time.

4. The Brush Sander Machine is equipped with a high-end frequency conversion speed regulating device, which can adjust the appropriate speed according to different plates to ensure the efficiency of the work and the effect of sanding.

5. Ensure the stability and service life of the sanding machine.

6. The special-shaped sanding machine has strong adaptability, which can improve the dimensional accuracy of the work and the surface roughness of the workpiece.

7. The shape sanding machine can process workpieces with a large width, as well as narrow workpieces.

8. The shape sanding machine can process all kinds of flat surfaces, as well as all kinds of curved surfaces.

9. The special-shaped sanding machine can be used for large-scale production as well as small-batch production.

10. The special-shaped sanding machine reduces the wear of the contact roller of the work head, improves the sanding accuracy, and realizes the automatic adjustment of the sanding process.

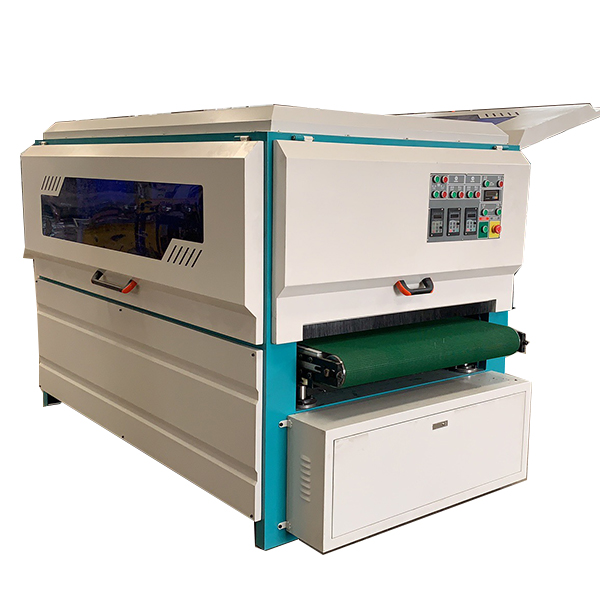

Products Show