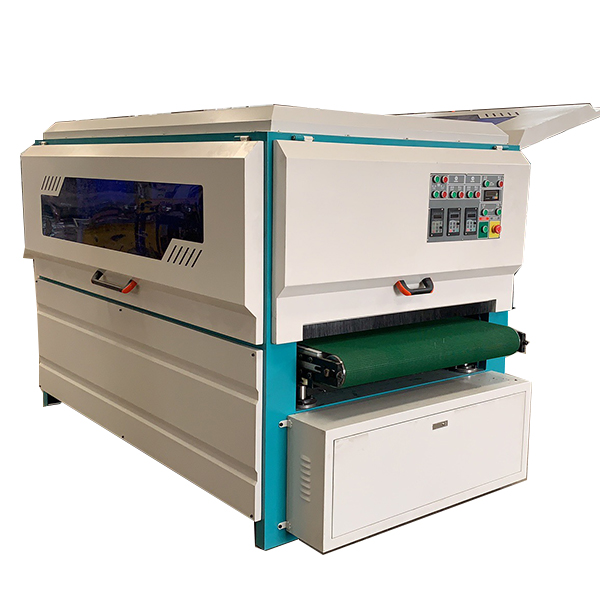

Wire Brush Sanding Machine

Wire Brush Sander Description

The working principle of the Wire Brush Sander: The wire drawing machine is composed of a wire drawing part and a winding part. The wire drawing part is composed of a wire drawing wheel, a mold holder, and a mold. After the wire passes through the mold, it is wound on the wire drawing wheel. During operation, the winding wheel runs to provide the traction tension of the wire. Under the action of the traction tension, the wire is wound through the drawing wheel to pass the wire through the drawing die, so that the wire is continuously changed from thick to thin, so as to obtain wires of different wire gauges.

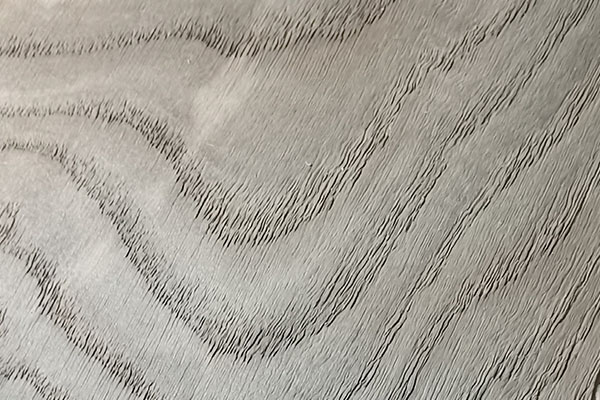

Wire Brush Sander are mainly used for surface frosting, wire drawing, drawing, etc. of stainless steel coils, stainless steel plates, aluminum plates, aluminum coils, signs, decorative panels, etc. After processing, the surface of the workpiece is smooth and smooth, and the silk grain is beautiful, without shadows or transitions. Strips or uneven textures, etc. This series of machines are economical and durable in use, wide in scope, and low in processing costs.

Product Parameters

| Machine configuration | Wire Brush Sander | ||

| Effective width | 1300mm | ||

| Effective thickness | 2-130mm | ||

| Feeding speed | 0-18m/min | frequency conversion speed regulation | |

| Drive roller size | φ130*1320 | ||

| Transmission power | 3kw | ||

| Electric | Chint | ||

| Inverter | Jintian | ||

| Non-slip belt | |||

| First group | Horizontal steel wire φ200*1320 | Steel wire diameter 0.5mm | Motor 11kw-6 |

| The second group | Horizontal steel wire φ200*1320 | Steel wire diameter 0.3mm | Motor 11kw-6 |

| The third group | Vertical relief | Steel wire diameter 0.25mm | Motor 2.2kw-4 (6 motors) |

| The fourth group | Vertical relief | Steel wire diameter 0.25mm | Motor 2.2kw-4 (6 motors) |

| The fifth group | horizontal polishing φ200*1320 | grinding wire diameter 1.2mm | motor 7.5kw-4 |

| The sixth group | horizontal polishing φ200*1320 | grinding wire diameter 0.8mm | motor 7.5kw-4 |

Note: 1. Each set of rollers can be raised and lowered electrically and manually, and 6 sets of rollers can also be raised and lowered at the same time.

2. Each set of rollers is frequency-converted and speed-regulated.

3. The conveying speed is controlled by frequency conversion.

Factory scene

Product details